Dynovel visited the American Coating Show (USA) from April 30th to May 2nd, 2024, and surveyed a sample of 52 Companies & Professionals, all offering coating solutions (Binders, Solvents, Pigments, Additives…) to the industry.

1. Companies & Professionals surveyed

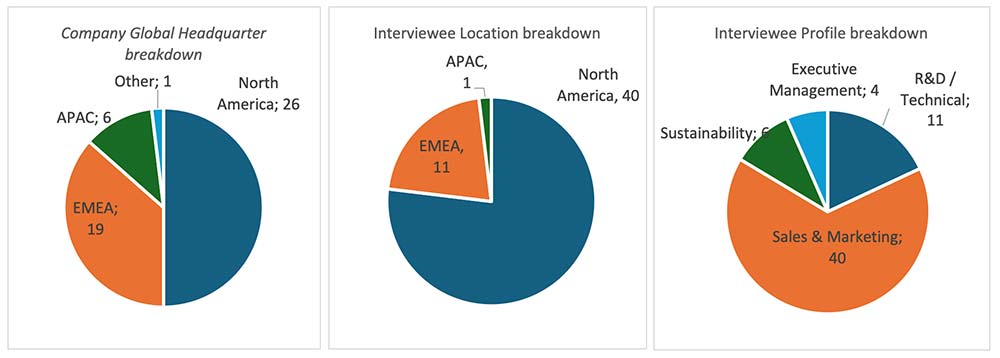

50% of the interviewees are working for American companies, 30% for European companies and 20% for companies in APAC. Most of the interviewees (about 75%) are based in North America.

12% of interviewees are involved in a Sustainability role, and the majority occupies a function in Sales & Marketing. To be noted that some interviewees are sometimes involved in more than one function (for example Marketing & Sustainability or Technical & Marketing).

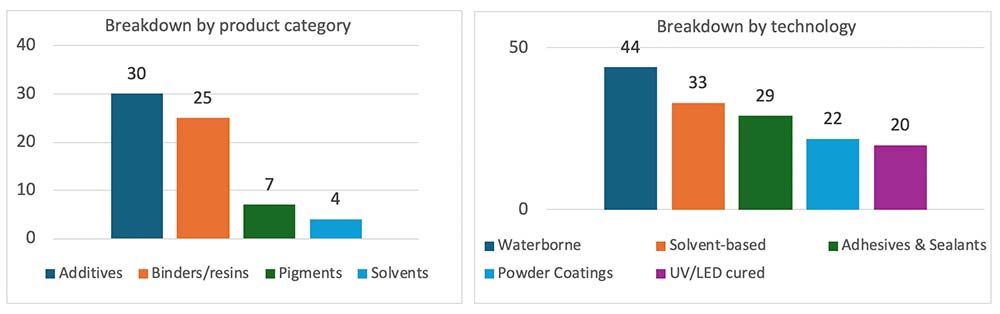

2. Product portfolio offered by the interviewed companies

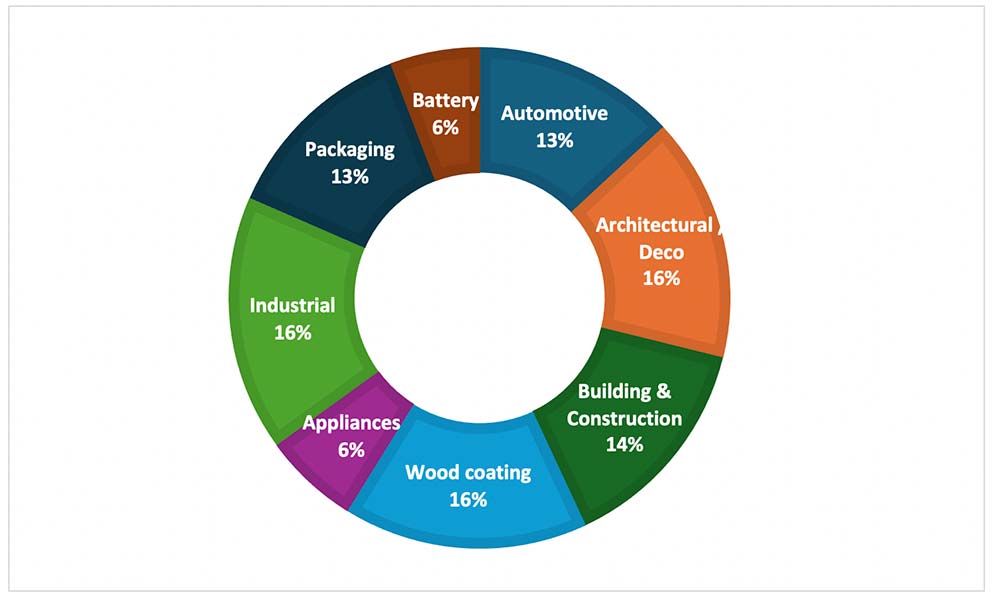

3. Markets served by the interviewed companies

4. Feedback on Sustainability

a) Companies’ Sustainable Development Goals (SDG) drivers

90% of the interviewees claimed that their companies have clear Sustainable objectives most of the time, published and available on Sustainability reports or their websites. Only 3 companies mentioned not having clear Sustainability goals.

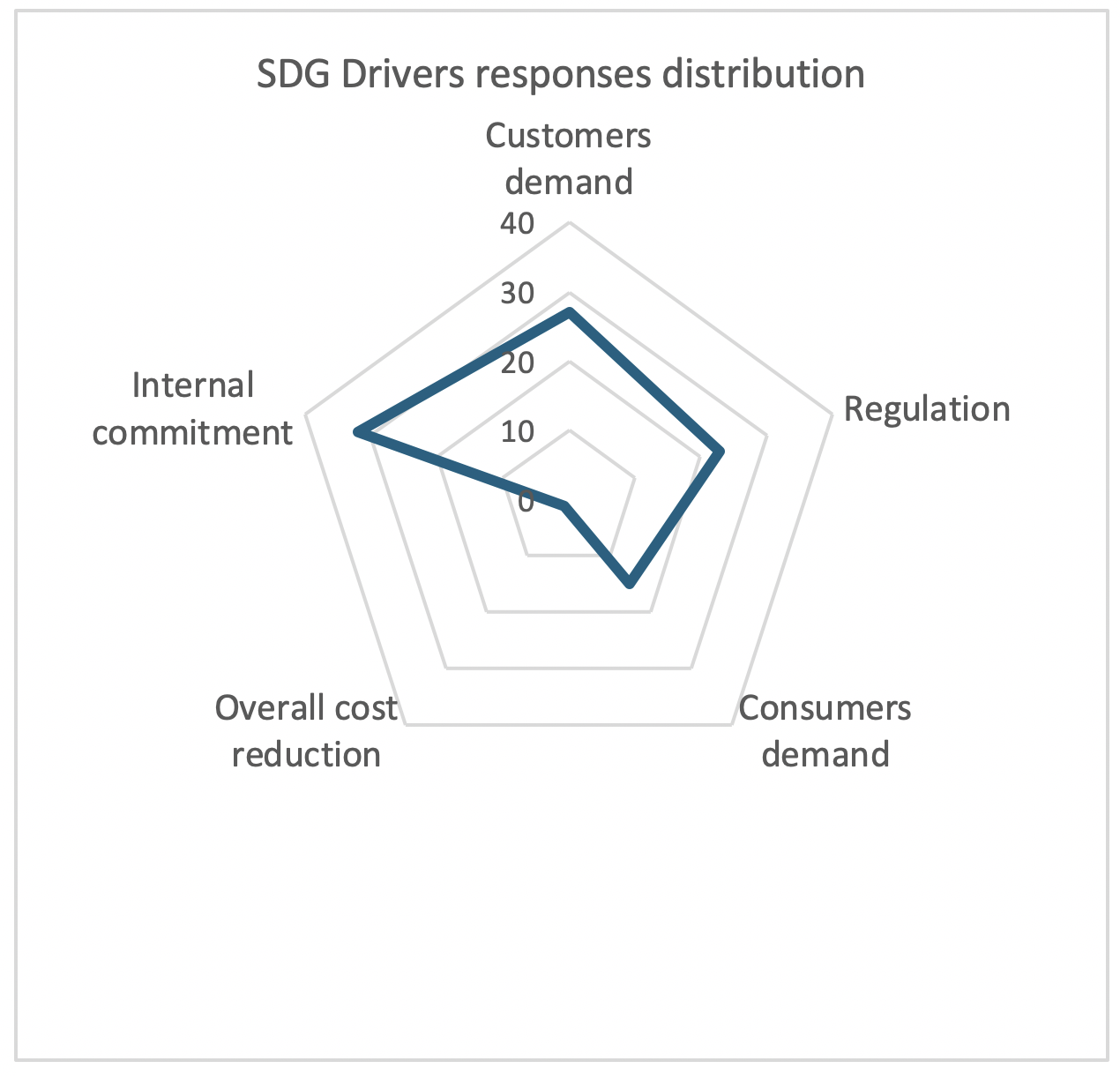

Among the main drivers to set up Sustainable Development Goals:

- #1 cited is Internal commitment (about 2/3 of the respondents), usually paired with Customer demand (ranked #2).

- 50% of the respondents emphasize Regulation as being a key driver.

- 30% mention that the Consumers have a key role in the Sustainability strategy of their company even though their direct business is at the BtoB level.

Only one company mentions the reduction of overall cost as being a driver.

b) Drivers for decarbonization of the Coating Industry

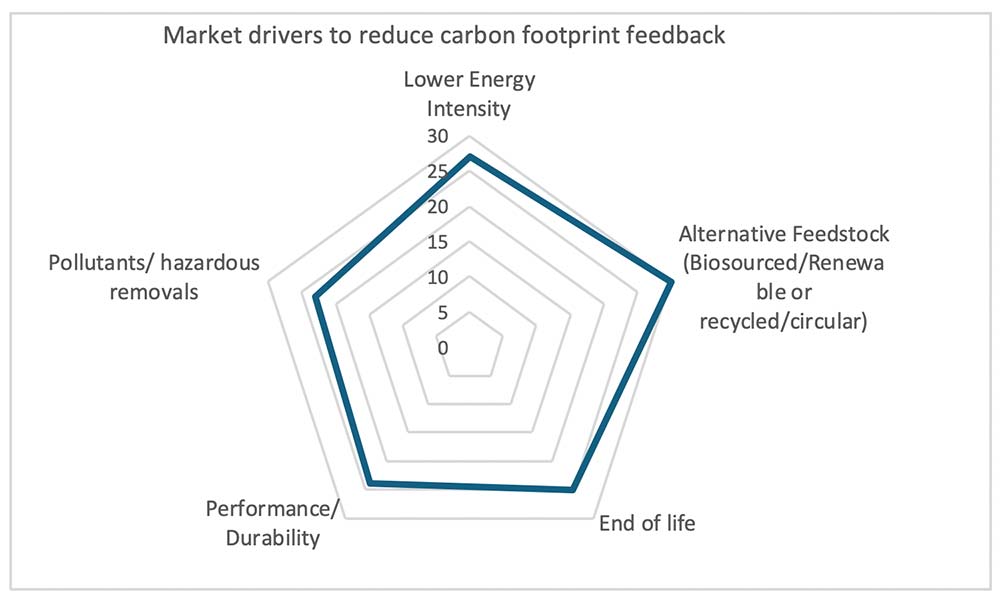

What are your customers’ drivers in their selection of coating solutions that have an impact on lowering the carbon footprint and offering more sustainable solutions to the market?

While Alternative Feedstock and Lowering Energy Intensity have ranked #1 and #2, none of the sustainability features stand out in the realm of the coating Industry.

Enabling a more sustainable End of Life (reuse, recyclability enablers, compostability, biodegradability…), improving the final products’ performance and lifetime, or removing pollutants in final products are just as important as offering alternative feedstock or low energy intensity products.

c) Interviewees’ positioning regarding Segregation, Mass Balance Approach, Traceability and Certification

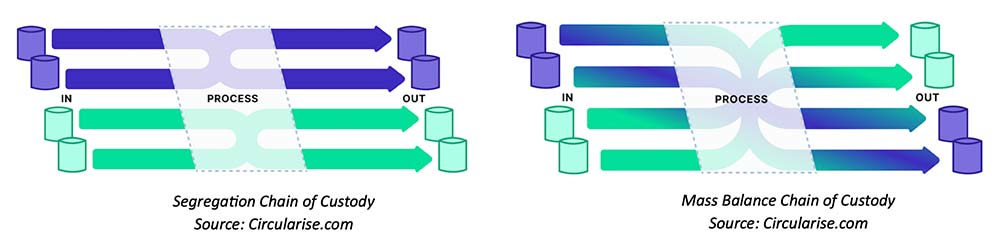

To help trace the origin and sustainability of products through the supply chain, two different approaches can be used: Segregation of Raw Materials or Mass Balance.

Product segregation definition

It involves physically keeping certified (e.g. bio-based) and non-certified products separate throughout the entire supply chain. This ensures that the certified products maintain their identity and integrity from production to the final product.

Mass Balance definition

Mass balance allows for the mixing of certified and non-certified products at certain points in the supply chain. The key is to maintain an overall balance, ensuring that the quantity of certified products entering the supply chain is equal to the quantity of certified products leaving it.

Traceability

System in place to trace the amount of certified content in the final product involving tracking and accounting for the volumes of certified and non-certified materials at various stages of the supply chain.

Certification Assurance

Mass Balance is a more flexible and practical approach. However, in comparison to product segregation approach, there is ambiguity on the sustainable content as it is only attributed.

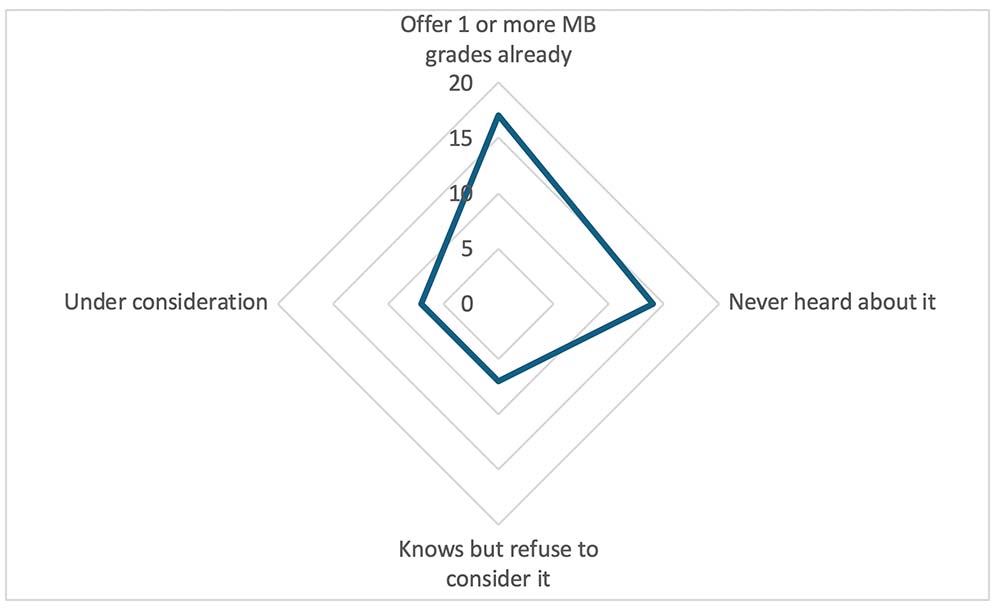

Does your company use the Mass Balance approach to trace bio-allocated content and develop sustainable solutions?

38% of respondents already have ISCC+ certification for some of their plants and have at least 1 Mass Balance grade in their offer. On the other hand, 31% have never heard about ISCC+ or Mass Balance Approach.

This number clearly shows that the market still needs to be educated on the Mass Balance Approach so that companies can decide whether they want to use this attribution method as an additional way to reduce the carbon footprint.

16% of the participants acknowledged that they are currently evaluating the possibility to integrate the Mass Balance Approach into their offer and considering starting an ISCC+ certification process, while the exact same number of companies (16%) have specifically mentioned knowing about Mass Balance but refusing to apply it. For the latter, product segregation is their clear positioning to guarantee the Bio-content of their sustainable solutions.

5) Our conclusion

There is not a single sustainable offer to address the needs of coatings end-users and the breadth of end-use applications. The answer lies in the availability of multiple options that will fit customers’ specific needs depending on their location, their size, their technology & manufacturing process, SDG goals and their own customers & markets.